Repetitive loading is known to weaken components over time, sometimes leading catastrophic failure. Engineering textbooks are full of examples of large structures that have failed to survive forces much lower than what they were designed to withstand. This is due to a phenomenon known as fatigue. Small defects, invisible to the human eye, grow as the component is loaded repeatedly. Failure analysis of retrieved prostheses often reveals features in the fracture surface characteristic of fatigue.

However, having tested the implant system under repeated loading under conditions mimicking the ones in their intended application, patients and manufacturers can be assured that the implant will survive its design life.

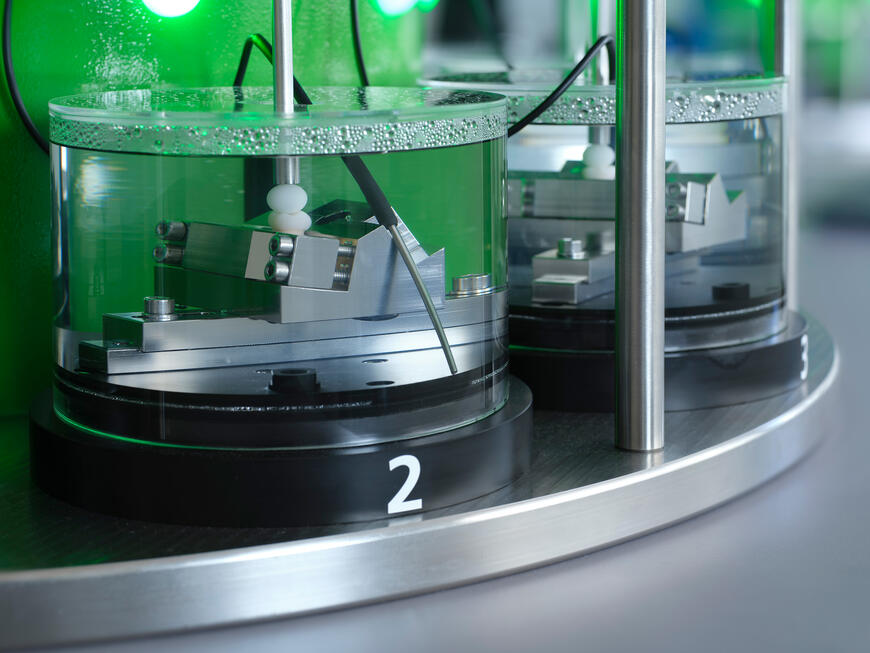

The DYNA5dent testing machine is an off-the-shelf testing installation produced by DYNA-MESS Prüfsysteme GmbH. Each machine can run five parallel tests completely independent of each other. The machines are also supplied with a temperature control unit which circulates water in the chamber enclosing the test specimen. This means tests also take into consideration important defect growth mechanisms such as corrosion fatigue.

With two DYNA5dent machines in their laboratory, NIOM can run ten parallel in vivo tests with high precision. This means they can efficiently provide representative test results in accordance with ISO14801. The results are specific to each implant system design. NIOMs aim is to use this capability to ensure implant systems on the Nordic market are safe and to enhance their research on related material properties.