Thermocycling requires moderately sophisticated equipment to ensure constant temperatures in the water baths and properly timed transfer of the specimens. NIOM designed its first thermocycling apparatus 20 years ago, and has since supplied numerous laboratories with the equipment, each incorporating developments in temperature and mechanical control. While international standards specify immersion times and temperatures for established tests, new materials and test methods create new situations for which thermocycling is a useful method of ageing the materials. In each case, however, the physical process requires analysis. Thermocycling is based on the diffusion of heat, and in porous materials also of moisture, in and out of the test specimen. A diffusion process always acts to even out differences.

The questions that need to be answered are:

- How quickly do gradients in temperature or moisture content fade?

- How large are the transient mechanical and chemical stresses that are imposed?

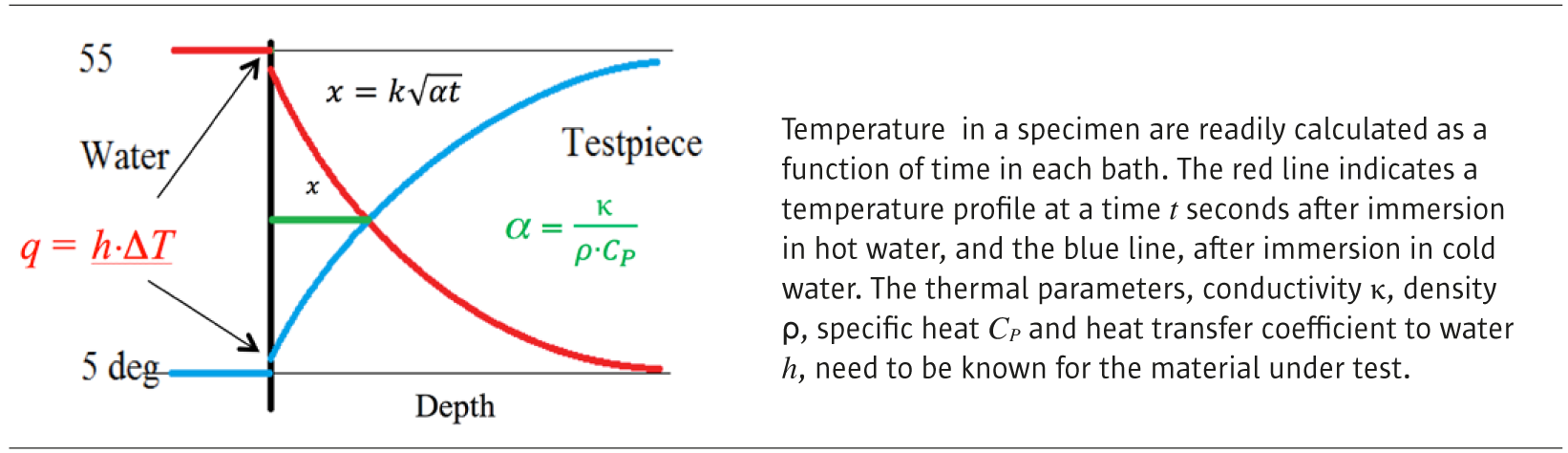

Heat transfer is a classic field of engineering that gives us the necessary equations. Once the thermal parameters and diffusion properties of a material are available, the temperature throughout the test specimen may be calculated for times after immersion in each bath. NIOM has written software to calculate temperature profiles and the resulting mechanical stresses for both round and square specimens. The flow rate of water past the specimen determines how quickly the specimen achieves the temperature of its bath, and thereby the period required for each thermocycle.