NIOM aquires open material 3D-printer

As an accredited test facility, NIOM maintain a comprehensive instrument park.

While surveying the market, it quickly became clear that an open material system 3D-printer would add many benefits.

-We are very pleased with our choice. Dr. Kopperud says.

3D-printing techniques and possibilities were among the main features of this year’s IDS trade fair in Cologne. These printers open up exciting new fields of research, treatment and testing, making one a natural acquisition for NIOM’s instrument park.

– We saw that a 3D-printer would add speed and predictability to our production of test specimens, says Dr. Hilde M. Kopperud, Head of Laboratory at NIOM.

Among other things, a 3D-printer will enable NIOMs personnel to prepare printable resin specimens in-house, in addition to using traditional preparation techniques.

The printer would also open up new possibilities in test design, especially within research and development. However, which printer to acquire, was not a given.

Accredited testing

– As an accredited test laboratory, according to ISO/IEC 17025, and an advanced research facility, we already maintain a comprehensive instrument park. We hold high standards, Dr. Kopperud says.

To illustrate, the recent acquisitions include the Hitachi TM4000, a tabletop Scanning Electron Microscope, and a UHPLC-MS (Ultra High Performance Liquid Chromatography- triple quadrupole mass spectrometry).

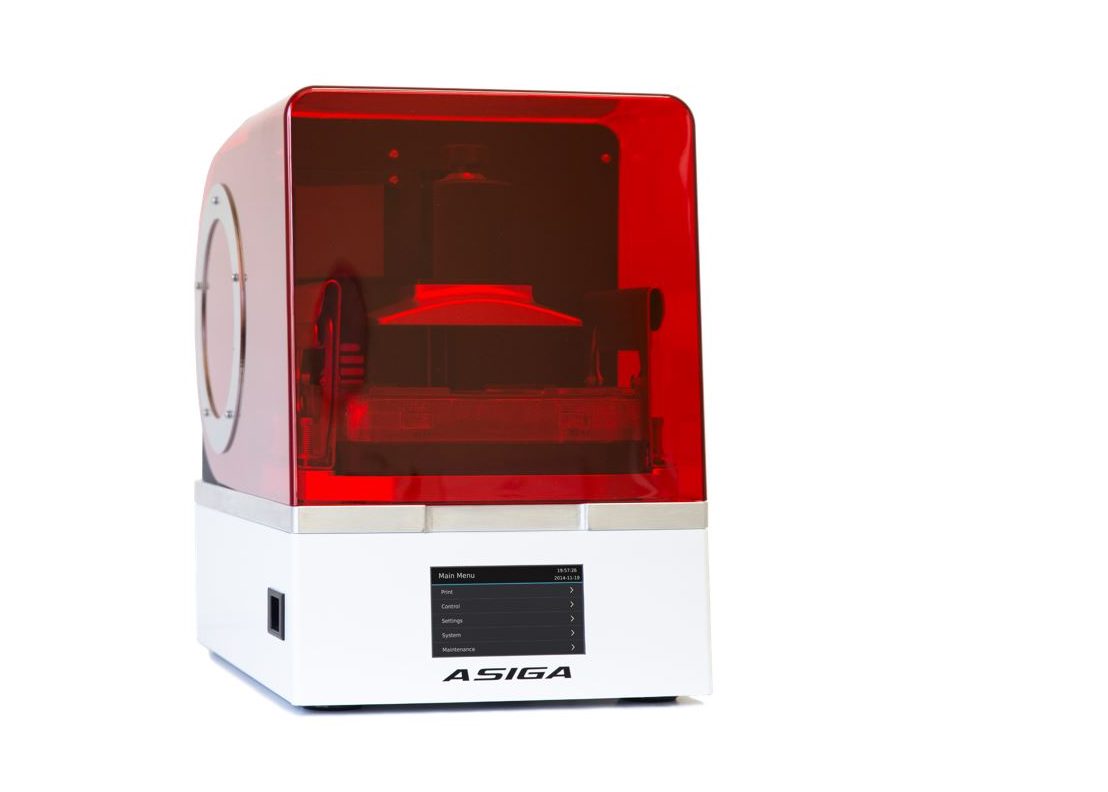

The Asiga Max UV

– After surveying the market, we ended up choosing the Asiga MAX UV 3D printer, Dr. Kopperud says.

Asiga MAX UV 385 nm is a DLP (digital light processing) printer and can operate at variable increments in the Z resolution down to 1-µm adjustments. Combined with a pixel resolution of 62 µm, a high accuracy of every print is assured.

– For us it means that we can readily achieve the high surface quality, and precision, that is needed for dental specimens, Dr. Kopperud says.

Open source

It is also important for NIOM that the Asiga MAX UV is an open material system 3D-printer.

– This means it is able to print material from many different manufacturers, of both dental and non- dental materials, Dr. Kopperud explains.

This opens up possibilities for use, as the selection of materials available for printing is vast, and growing. It already includes temporary restorative materials and dentures, models and auxiliary materials, as well as waxes for investments and casting.

– So far, we are very pleased with our choice. It has, among other things, printed parts for our new mechanical masticator, a device designed by our engineers and toolmakers for the evaluation of wear, Kopperud adds.

Get in touch at niom@niom.no for more information and a quotation for our technical assistance.

NIOM Newsletter for clients and partners Q3 2019