NIOM has recently acquired a new hardness tester (Figure 1). The instrument is used in a range of different research projects at NIOM. One example is the effect of abrasion and erosion on surface hardness of different dental materials (Figure 2). Two visiting researchers are investigating the results of different treatment methods to improve the surface of molarincisor-hypomineralization (MIH)-affected teeth.

NIOM has recently acquired a new hardness tester (Figure 1). The instrument is used in a range of different research projects at NIOM. One example is the effect of abrasion and erosion on surface hardness of different dental materials (Figure 2). Two visiting researchers are investigating the results of different treatment methods to improve the surface of molarincisor-hypomineralization (MIH)-affected teeth.

Hardness is an important mechanical property of dental materials and is defined as the resistance to permanent surface indentation. Sufficient hardness ensures that the placed restorations are resistant to in-service scratching, from both mastication and abrasion.

The instrument is configured to carry out two types of microhardness testing; Vickers and Knoop. In both methods a standardized load

The instrument is configured to carry out two types of microhardness testing; Vickers and Knoop. In both methods a standardized load

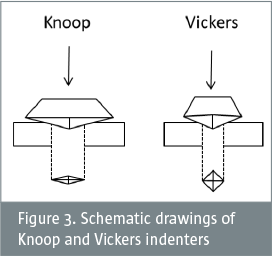

is applied to a fixed point on the sample. This creates a symmetrically shaped indentation, which can be measured and the hardness of the material calculated. In the Vickers hardness test, a diamond in the shape of a square-based pyramid is used to make the indentation with a force load ranging from 100 g to 30 kg. In contrast, the pyramid-shaped diamond indenting tool used in the Knoop method has a more narrow and elongated base and a lower load is applied (20 g to 2 kg) (Figure 3).

Traditionally, Vickers is used to measure the hardness of very hard and brittle materials, such as cast dental alloys, but is also applicable to softer materials. Knoop has been used for a wider range of materials, from amalgam and ceramics to resin-based composites, but is also useful for materials that vary in hardness over an area of interest, such as enamel and dentin.

Traditionally, Vickers is used to measure the hardness of very hard and brittle materials, such as cast dental alloys, but is also applicable to softer materials. Knoop has been used for a wider range of materials, from amalgam and ceramics to resin-based composites, but is also useful for materials that vary in hardness over an area of interest, such as enamel and dentin.

![]() Download the August newsletter

Download the August newsletter