Molecules interact with light over a wide wavelength range, and the interaction between light and molecules will form a pattern that can give us detailed information about the structure of the molecule.

Infrared spectroscopy is one of the most widely used techniques for identification of chemical compounds and materials, including liquids, solid substances and gases, through their ability to characterize absorption of infrared radiation.

There are four most used sampling techniques in FTIR depending on what type of samples and consistency it is:

• Transmission

• Attenuated Total Reflection (ATR)

• Specular Reflection

• Diffuse Reflectance

Degree of conversion

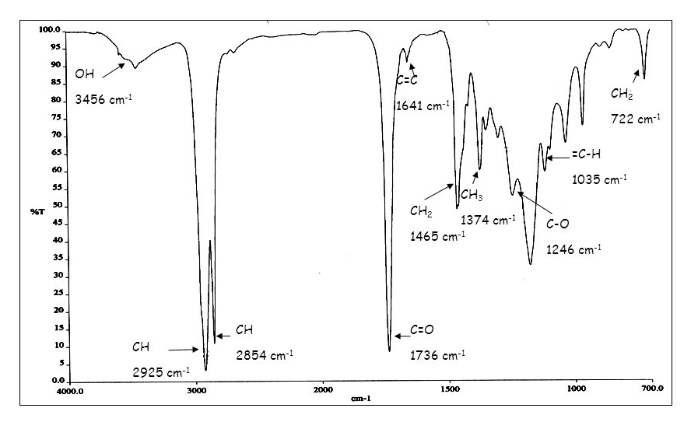

The degree of conversion (DC) is a measurement of the curing of a resin-based material. FT-IR may be used to determine the DC. The method calculates the conversion of reactive methacrylate groups in the material. The calculation is based on ratios of area or height of specific peaks in the FTIR-spectrum of the material.

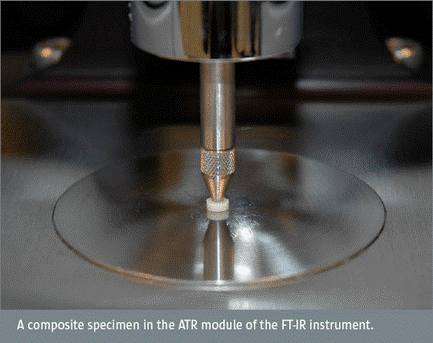

The ATR technique may be used to measure DC at different depths of a material, for instance a cylinder may be used to prepare samples of varying thickness. This method is particularly relevant for light-curing composite materials, where the layering of the material in the restoration is an issue. The material may then be cured from the top surface using an ordinary curing unit in a setup resembling the in situ curing. The method can be used for evaluation of bulk-fill materials for which thicker layers (e.g. 4 mm) are used, compared to conventional composites.

NIOM may perform measurements of degree of conversion of restorative materials and other polymer-based biomaterials using our FTIR instrument. We have equipment for measuring transmission and reflection (ATR) as well as a DRIFT accessory (diffuse reflectance) for powder samples.