Dental materials are subject repeatedly to masticatory forces, both directly on an occlusal surface, and indirectly through interactions with an abutment or via a connecting unit.

Repetitive loading on components is known to weaken them to the degree that they can fracture catastrophically. Engineering textbooks are full of examples of large-scale structures that have failed to survive forces much weaker than they were designed to tolerate. The phenomenon is called material fatigue. Failure analysis of retrieved prostheses often reveals features in the fracture surface characteristic of fatigue.

Test instruments designed to study material fatigue have, until recently, been driven hydraulically, intended for testing of big constructions with high applied forces. In classical fatigue studies, these instruments are employed to determine the number of cycles of a given load or range of loads that a material can withstand. More recently instruments employing electromagnetic forces with the ability to apply low to moderate loads have become available.

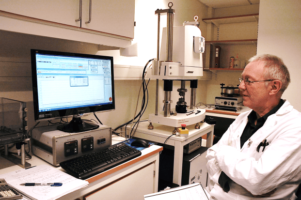

Because dynamical testing makes it feasible to estimate the expected lifetime of a restorative or prosthetic material, NIOM decided to add a dynamic test machine to our laboratory instrumentation. The instrument is a Bose Electroforce 3330 with a 37 °C temperature chamber designed for dynamic fatigue testing.

However, repetitive loading induces other effects than fatigue that contribute to the degradation of materials. This makes it equally interesting to study the impact of dynamic loading without any breakage. The ageing of ceramic materials under chewing forces in a humid environment is one example.

Corrosion and leaching are two forms of chemical degradation that are accelerated under dynamic loading. The first of NIOM’s investigations with the new instrument demonstrated an increase in the amounts of metallic ions leached out when the standard corrosion test for dental alloys is performed on plate specimens additionally subjected to over 400 000 cycles of elastic loading during its 7-day immersion in acid saline solution. For this experiment, NIOM built a metal-free solution chamber and bending jig.

Biological tissues show a different response to repetitive loading. Dynamic test instruments like NIOM’s are employed in tissue-engineering and osteoblast experiments to investigate how loading maintains and develops muscle tone and enhances bone repair. NIOM’s laboratories are equipped to support similar studies.